Notching Floor Joists Codification

So here is the complete updated notching floor joists code encompassing IBC Section 2308 & IRC R502.8 and related sections

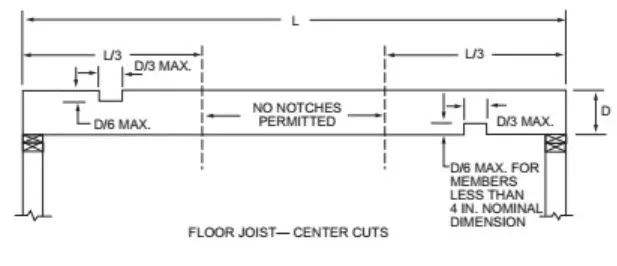

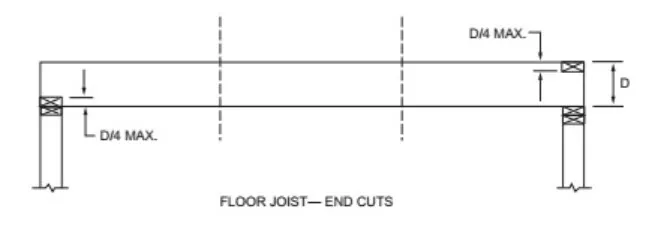

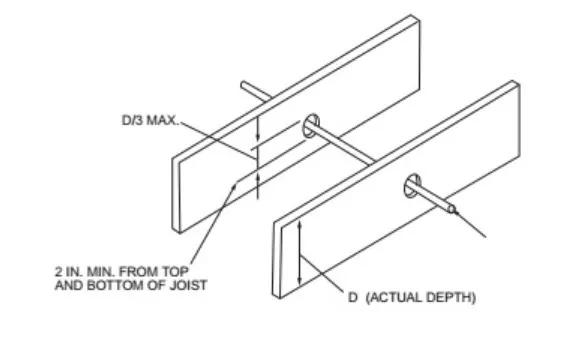

Floor joists occasionally need to be notched or drilled during construction, but you should take pre cautions not to weaken the structural strength of the framing member. First rule: Avoid notching a joist along the middle third of its length. However, drilling holes for wiring, etc. along this middle third is acceptable. The holes must be located a minimum of 2 in. from the top and bottom of the joist and from other holes. The maximum hole size is 1/3 the joist’s depth. You can cut a notch at the end of the joist to 1/4 of the joist’s depth (maximum). Along the outer third of a joist, you can cut a notch a maximum of 1/6 the joist depth and 1/3 the joist length without compromising its strength.

Notching Floor Joists Code

So let´s go with the notching floor joists code.

Notching should be avoided when possible, and holes bored in beams and joists create the same problems as notches.

When necessary, the holes should be located in areas with the least stress concentration, generally along the neutral axis of the joist. Limitations on the allowable cutting and notching of wood floor joists are meant to retain structural or functional integrity.

IBC 2308.8.2 Framing Details And Notching Floor Joists Code

Joists shall be supported laterally at the ends and at each support by solid blocking except where the ends of the joists are nailed to a header, band or rim joist or to an adjoining stud or by other means.

Solid blocking shall not be less than 2 inches (51mm) in thickness and the full depth of the joist. Notches on the ends of joists shall not exceed one-fourth the joist depth. Holes bored in joists shall not be within 2 inches (51 mm) of the top or bottom of the joist, and the diameter of any such hole shall not exceed one-third the depth of the joist.

Notches in the top or bottom of joists shall not exceed one-sixth the depth and shall not be located in the middle third of the span.

R502.8 Drilling and notching

Structural floor members shall not be cut, bored or notched in excess of the limitations specified in this section.

R502.8.1 Sawn lumber

Notches in solid lumber joists, rafters and beams shall not exceed one-sixth of the depth of the

member, shall not be longer than one-third of the depth of the member and shall not be located in the middle one-third of the span.

Notches at the ends of the member shall not exceed one-fourth the depth of the member. The tension side of members 4 inches (102 mm) or greater in nominal thickness shall not be notched except at the ends of the members.

The diameter of holes bored or cut into members shall not exceed one-third the depth of the member. Holes shall not be closer than 2 inches (51 mm) to the top or bottom of the member, or to any other hole located in the member.

Where the member is also notched, the hole shall not be closer than 2 inches (51 mm) to the notch.

R502.8.2 Engineered wood products

Cuts, notches and holes bored in trusses, laminated veneer lumber, gluelaminated members or I-joists are not permitted unless the effects of such penetrations are specifically considered in the

design of the member.

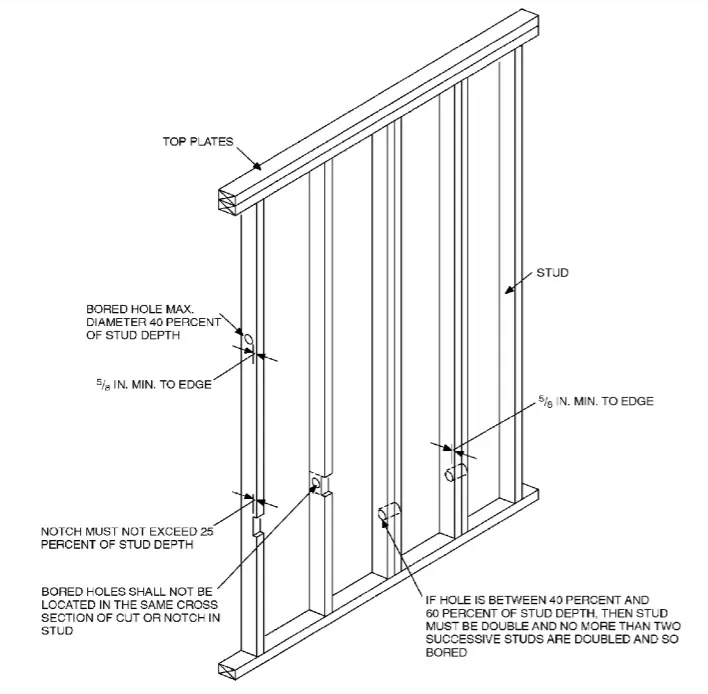

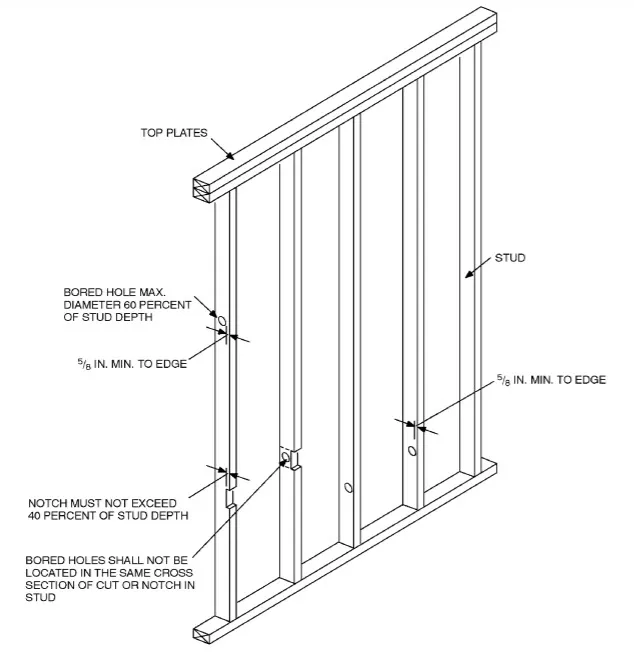

R602.6 Drilling and notching – studs

Any stud in an exterior wall or bearing partition may be cut or notched to a depth not exceeding 25 percent of its width. Studs in nonbearing partitions may be notched to a depth not to exceed 40 percent of a single stud width. Any stud may be bored or drilled, provided that the diameter of the resulting hole is no greater than 40 percent of the stud width, the edge of the hole is no closer than 5/8 inch (15.9 mm) to the edge of the stud, and the hole is not located in the same section as a cut or notch.

Exceptions:

A stud may be bored to a diameter not exceeding 60 percent of its width, provided that such studs located in exterior walls or bearing partitions are doubled and that not more than two successive studs are bored.

Approved stud shoes may be used when installed in accordance with the manufacturers recommendation.

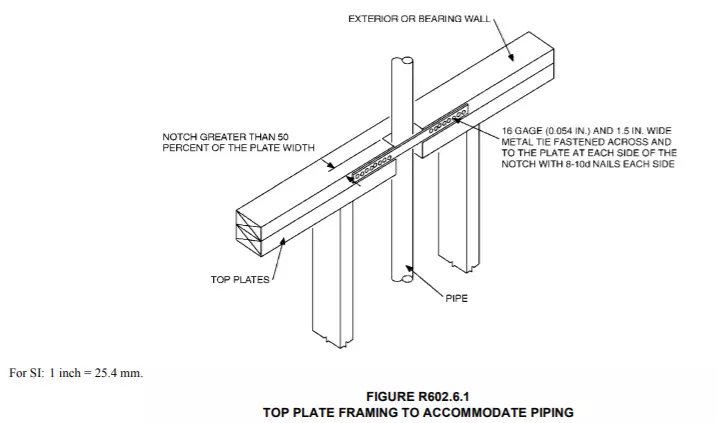

R602.6.1 Drilling and notching of top plate

When piping or ductwork is placed in or partly in an exterior wall or interior load-bearingwall, necessitating cutting, drilling or notching of the top plate by more than 50 percent of its width, a

galvanized metal tie of not less than 0.054 inches thick (1.37mm) (16ga) and 11/2 inches (38mm) wide shall be fastened to each plate across and to each side of the opening with not less than eight 16d nails at each side or equivalent. See Figure R602.6.1.

Exception: When the entire side of the wall with the notch or cut is covered by wood structural panel sheathing.

R802.7 Cutting and notching

Structural roof members shall not be cut, bored or notched in excess of the limitations

specified in this section.

R802.7.1 Sawn lumber

Notches in solid lumber joists, rafters and beams shall not exceed onesixth of the depth of the

member, shall not be longer than one-third of the depth of the member and shall not be located in the middle one-third of the span. Notches at the ends of the member shall not exceed one-fourth the depth of the member.

The tension side of members 4 inches (102 mm) or greater in nominal thickness shall not be notched except at the ends of the members. The diameter of the holes bored or cut into members shall not exceed one-third the depth of the member.

Holes shall not be closer than 2 inches (51mm) to the top or bottom of the member, or to any other hole located in the member. Where the member is also notched, the hole shall not be closer than inches (51 mm) to the notch.

Exception:

Notches on cantilevered portions of rafters are permitted provided the dimension of the remaining portion of the rafter is not less than 4-inch nominal 102 mm) and the length of the cantilever does not exceed 24 inches (610 mm).

R802.7.2 Engineered wood products

Cuts, notches and holes bored in trusses, structural composite lumber, structural glue-laminated members or I-joists are prohibited except where permitted by the manufacturer’s recommendations or where the effects of such alterations are specifically considered in the design of the member by a registered design.